FPS universal milling an drilling machine

FPS 425M-NC Dualmaster

Technical data

FPS 425M-NC |

|

|---|---|

Operating area |

|

| X-axis | 425 mm |

| Y-axis | 450 mm |

| Z-axis | 400 mm |

| Milling head can also be moved further along the Y-axis | 150 mm |

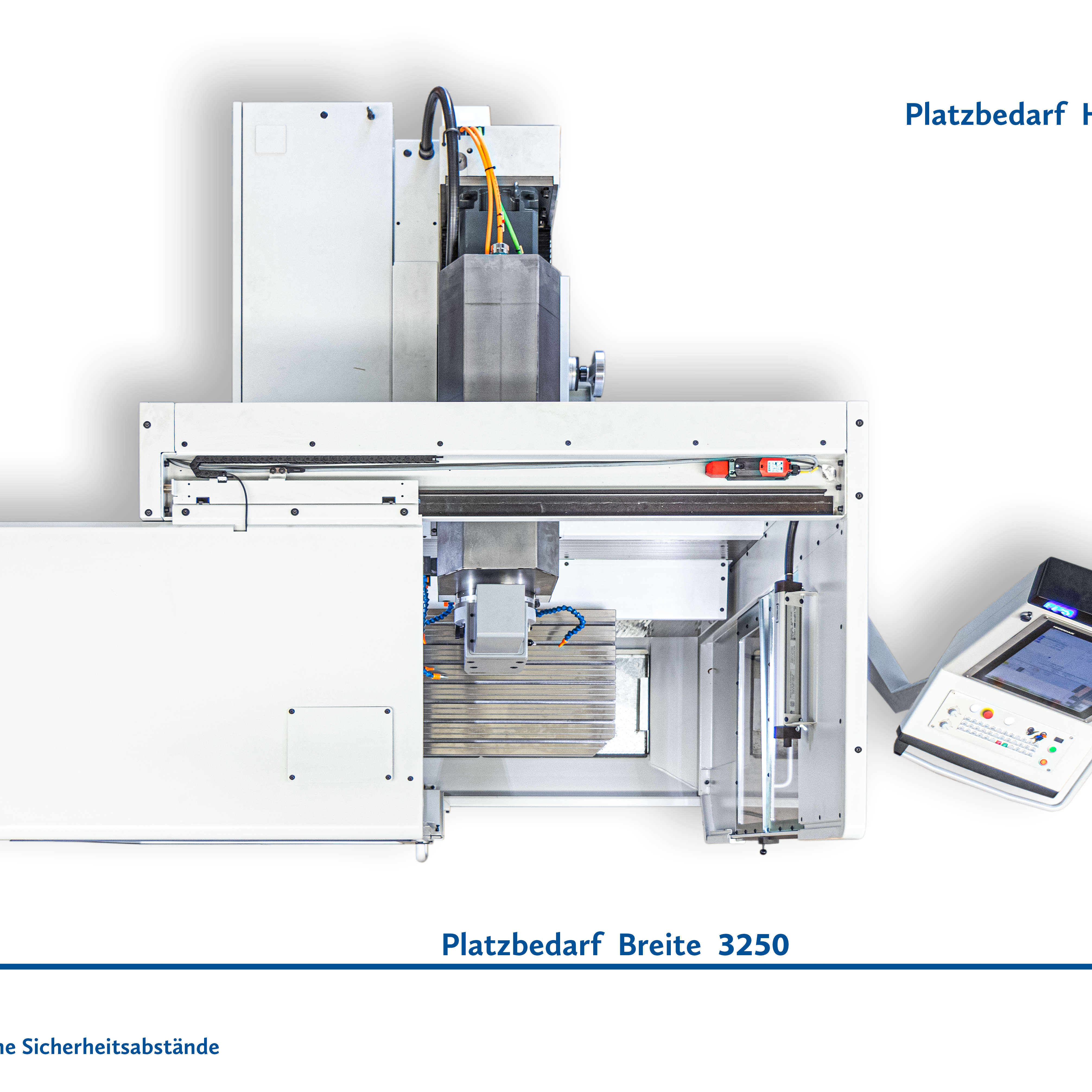

| W x D x H space | 3250 x 2300 x 2215 mm |

Fixed table |

|

| Fixed Table/clamping surface | 630 x 470 mm |

| T-grooves: Number / width / distance | 6 / 14H12 alignment groove 12H7 / 63 mm |

| Permitted load | 350 kg |

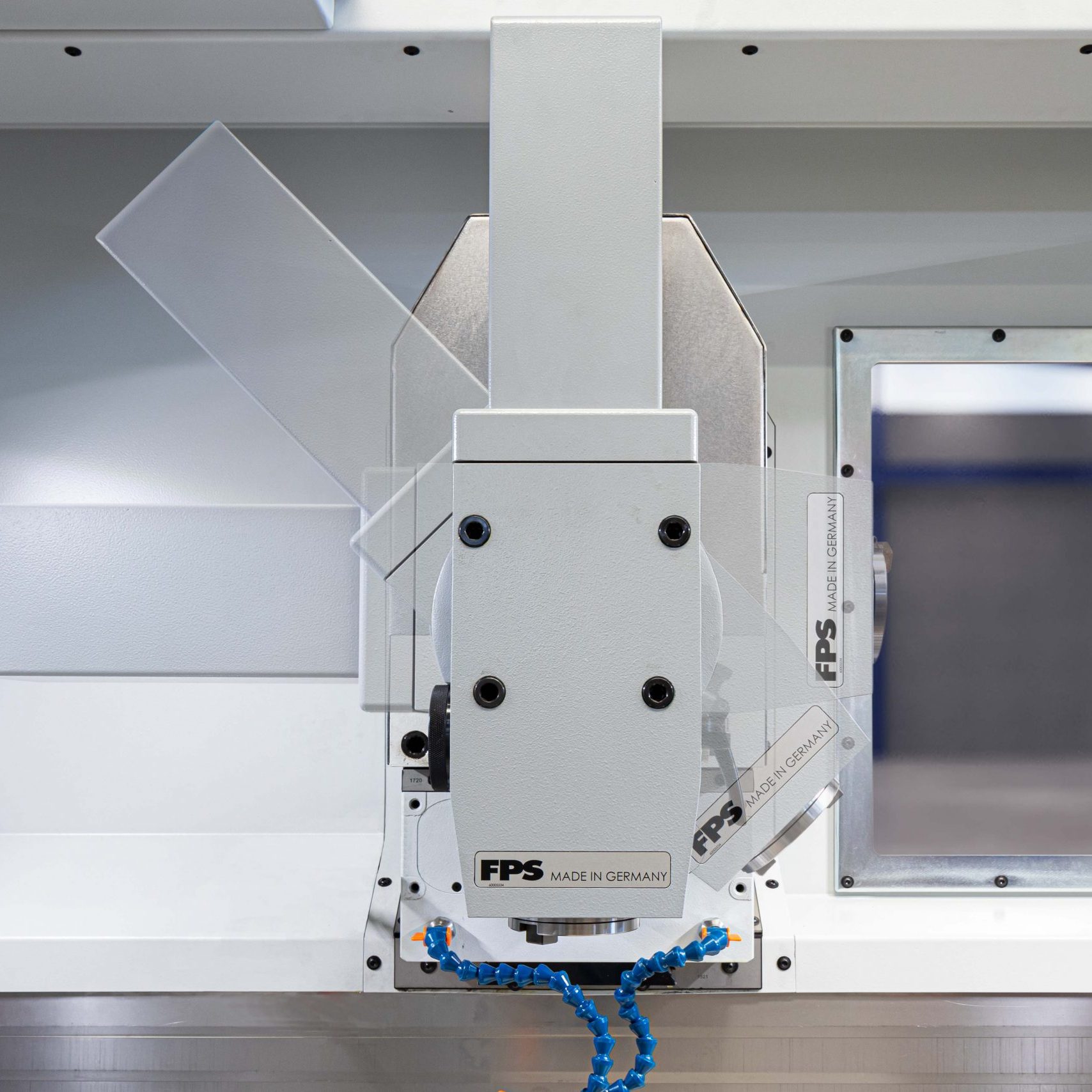

Operating spindle |

|

| Vertical and horizontal | horizontal (optional) |

| Vertically extending as drill spindle, with clamp/stroke | approx. 80 mm |

| Manually rotating milling head | +/- 90° |

Tool holder |

|

| with hydraulic tool clamping | ISO 40 DIN 69871 |

Tightening system |

|

| Hydraulic tightening system | DIN 69872 (standard) DIN 2080 (optional) |

Main drive, three-phase-current brake motor |

|

| Power | 14,1 kW |

| Torque | 243 Nm |

| Spindle speed | 0 to 5000 rpm (stepless adjustable) |

Feed drive, digital drive |

|

| Feed rate, continuously variable | 0 to 10000 mm/min |

| Rapid feed | 10 m/min |

| Control wheel manual rotation | 2.5 mm |

Connection |

|

| Mains connection | 3 x 400 VAC 50 Hz 25 A |

| Max. prelim. fuse rating | 35 A |

| Mains configuration | TN-S connection type: Fixed connection |

Control cabinet electronics |

|

| CE-compliant in line with current regulations of professional associations | BGVA 3 / DIN EN 60204-1 |

Weight |

|

| Total machine weight incl. machining table, milling head, cabin and control cabinet | approx. 2640 kg |