FPS 425M-NC

Operation area

X: 425 mm

Y: 450 mm

Z: 400 mm

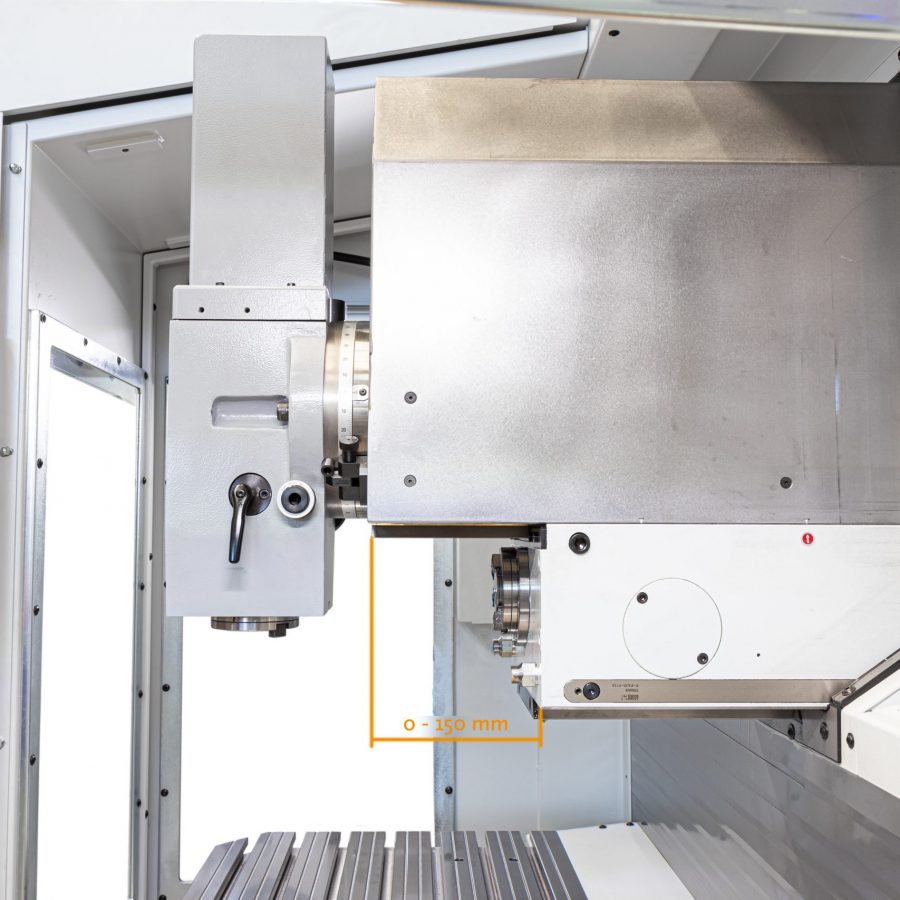

(The milling head can also be moved an additional 150 mm along the Y-axis)

Mehr Ergebnisse...

State-of-the-art CNC controls take control of our machine tools. To integrate our Dualmaster machines best possible into your existing manufacturing environment you have the choice between Siemens Sinumerik ONE or the HEIDENHAIN TNC 620 FS so that you can best integrate our Dualmaster´s into your existing manufacturing environment. The benefits range from intuitive touchscreen operation and powerful NC functions to networking for external program creation.

Operation area

X: 425 mm

Y: 450 mm

Z: 400 mm

(The milling head can also be moved an additional 150 mm along the Y-axis)

Operating area

X: 630 mm

Y: 450 mm

Z: 400 mm

(The milling head can also be moved an additional 150 mm along the Y-axis)

FPS 425M-NC | FPS 630M-NC |

|

|---|---|---|

Operating area |

||

| X-axis | 425 mm | 630 mm |

| Y-axis | 450 mm | 450 mm |

| Z-axis | 400 mm | 400 mm |

| Cutting head can also be moved further along the Y-axis | 150 mm | 150 mm |

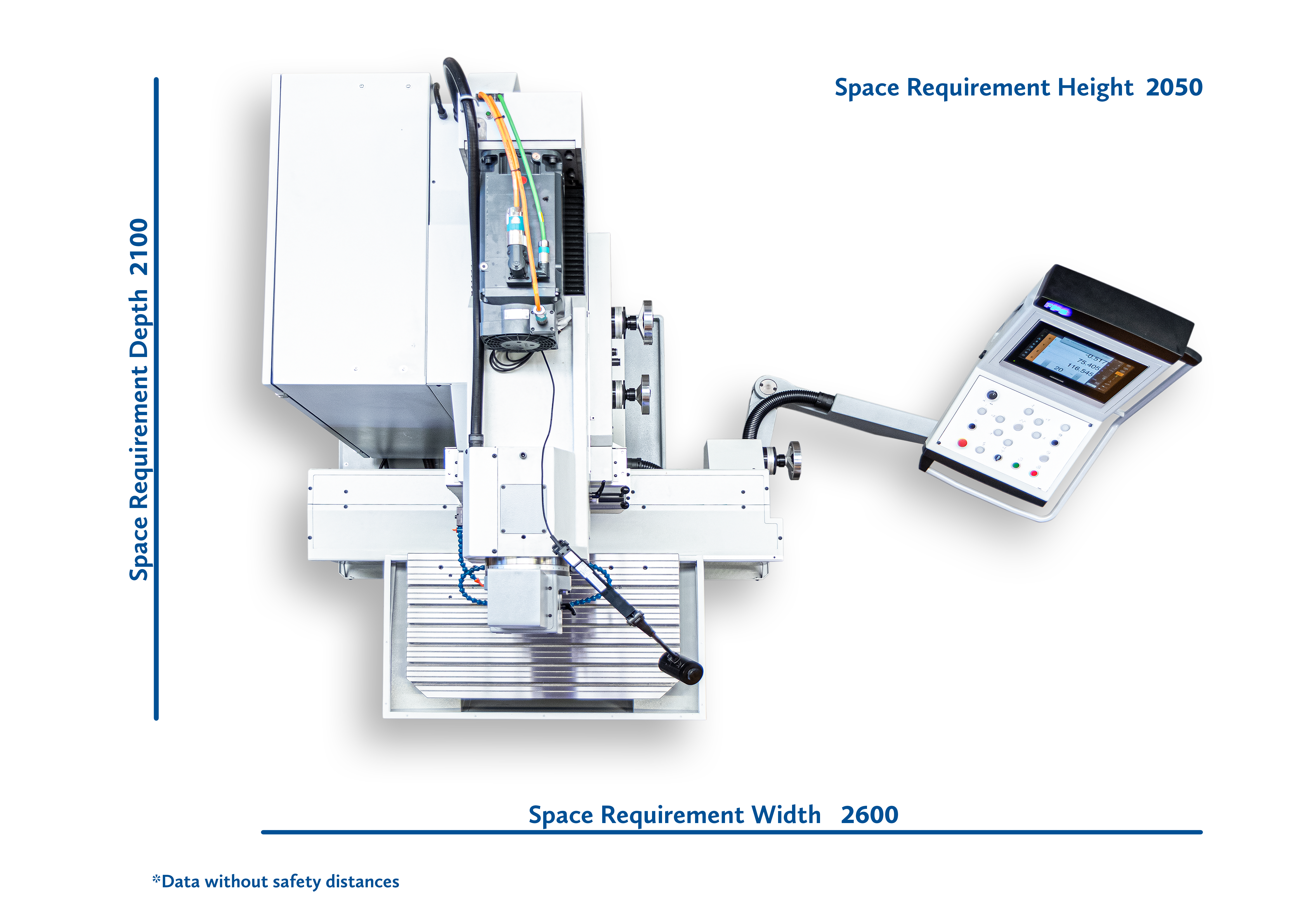

| W x D x H space | 3250 x 2300 x 2215 mm | 3250 x 2300 x 2215 mm |

Angle table |

||

| Table/clamping surface | 630 x 470 mm | 800 x 470 mm |

| T-grooves: Number / width / distance | 6 / 14H12 alignment groove 12H7 / 63 mm | 6 / 14H12 alignment groove 12H7 / 63 mm |

| Permitted load | 350 kg | 350 kg |

Operating spindle |

||

| Vertical and horizontal | horizontal (optional) | horizontal (optional) |

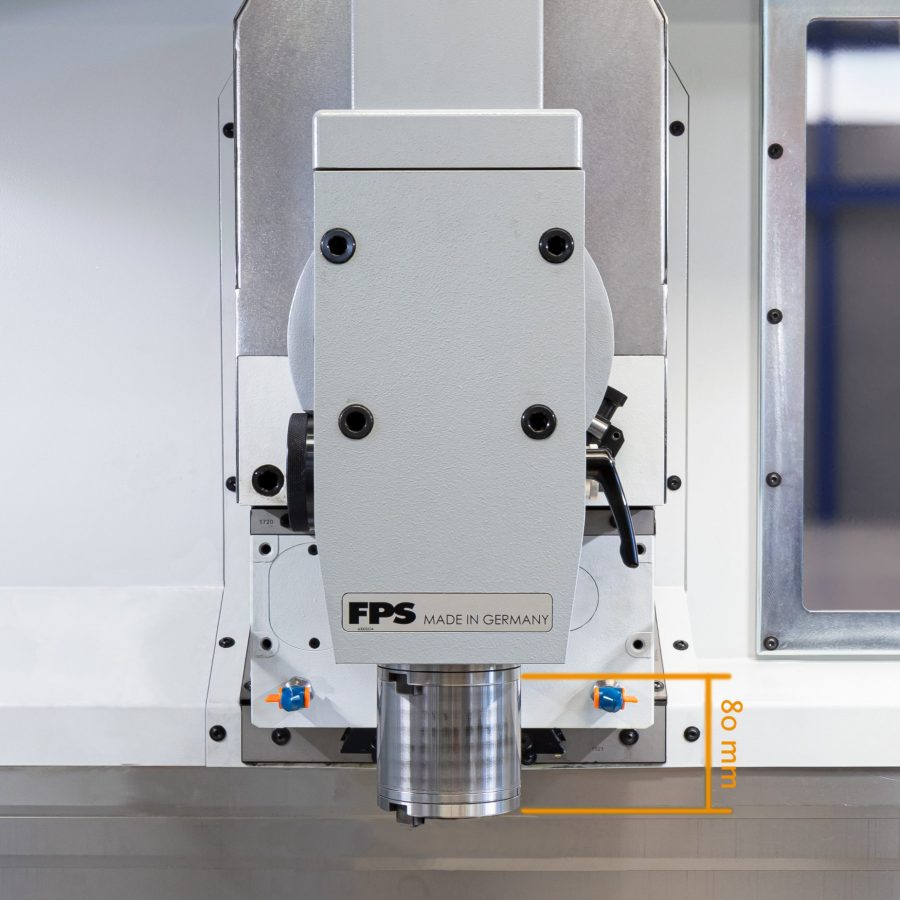

| Vertically extending as drill spindle, with clamp/stroke | approx. 80 mm | approx. 80 mm |

| Manually rotating cutting head | +/- 90° | +/- 90° |

Tool holder |

||

| with hydraulic tool clamping | ISO 40 DIN 69871 | ISO 40 DIN 69871 |

Tightening system |

||

| Hydraulic tightening system | DIN 69872 (standard) DIN 2080 (optional) | DIN 69872 (standard) DIN 2080 (optional) |

Main drive, three-phase-current brake motor |

||

| Power* (100/25% Duty cycle) | 8 / 15,2 kW | 8 / 15,2 kW |

| Torque* (100/25% Duty cycle) | 76 / 144 Nm | 76 / 144 Nm |

| Spindle speed | 20 to 5000 rpm (stepless adjustable) | 20 to 5000 rpm (stepless adjustable) |

Feed drive, digital drive |

||

| Feed rate, continuously variable | 0 to 10000 mm/min | 0 to 10000 mm/min |

| Rapid feed | 10 m/min | 10 m/min |

| Control wheel manual rotation | 2.5 mm | 2.5 mm |

Connection |

||

| Mains connection | 3 x 400 VAC 50 Hz 25 A | 3 x 400 VAC 50 Hz 25 A |

| Max. prelim. fuse rating | 35 A | 35 A |

| Mains configuration | TN-S connection type: Fixed connection | TN-S connection type: Fixed connection |

Control cabinet electronics |

||

| CE-compliant in line with current regulations of professional associations | BGVA 3 / DIN EN 60204-1 | BGVA 3 / DIN EN 60204-1 |

Weight |

||

| Total machine weight incl. machining table, cutting head, cabin and control cabinet | approx. 2640 kg | approx. 2640 kg |

| * Performance data refer to machines with Siemens Sinumerik ONE control system | ||

Whether for training or for use in the workshop – you want your machine tools to be versatile.

Our FPS 425M-NC and FPS 630M-NC Dualmasters are suitable for different operations and machining.

The user can operate the machine manually with handwheels or with the CNC control.

Machine conventionally or with the help of complex machining programs, which you create directly on the machine.

– our FPS 425M-NC or FPS 630M-NC Dualmaster is the right choice as a hybrid machine in any case.

Angular machining

Swivel the vertical milling head in any position to the right or left by each +/- 90°.

The number of degrees is adjustable by a scale.

By a lock the milling head is brought easily into vertical position again.

Extra Y – axis workspace

The vertical milling head can also be adjusted by 150 mm in the longitudinal axis. This allows you to increase your X-Y working area to

425 x 600 mm or 630 x 600 mm.

Milling or drilling

The vertical spindle is extendable by 60 respectively 80 mm and can be used as drilling pinole as well.

Locking vertical milling head

After swivelling the vertical milling head, it can be easily and quickly re-aligned to the vertical position by means of a locking device.

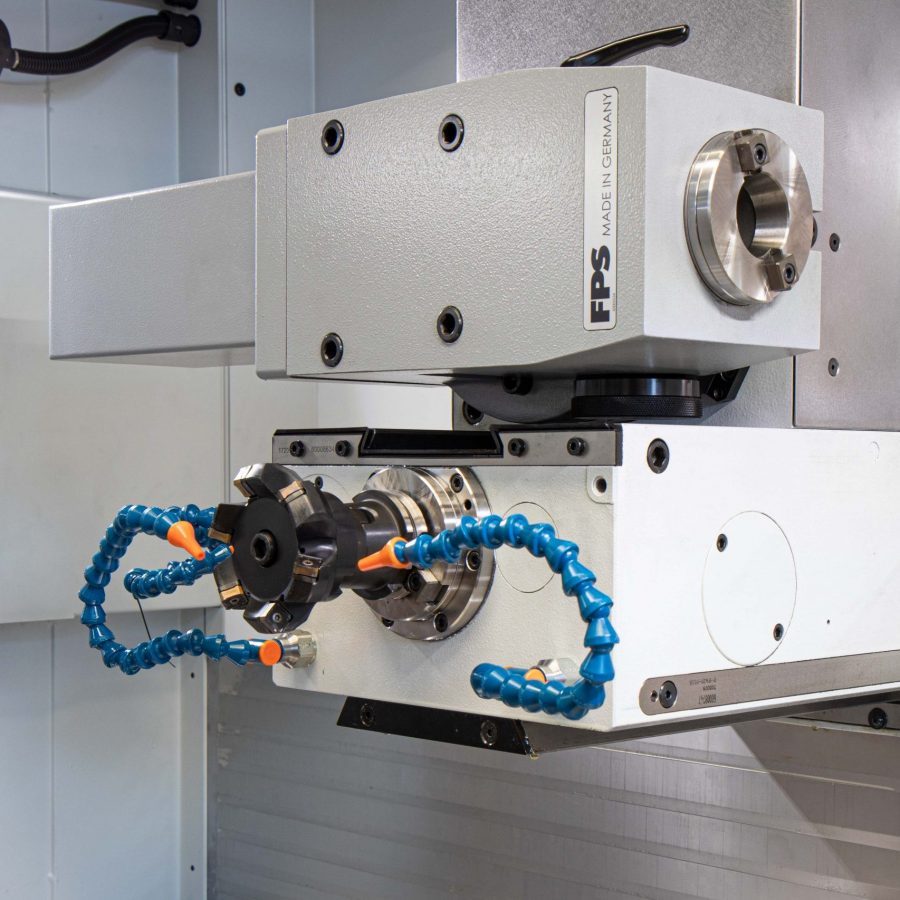

Coolant on the spindle mount

Articulated hoses can be used to ensure that the tool is supplied with coolant in any position.

Safety handwheels – Optional

Manual handwheels in all axles.

Horizontal machining – optional

For horizontal machining, the vertical milling head can be swivelled by 90° and cranked to the rear.

For horizontal machining, the vertical milling head does NOT have to be dismantled, it is moved to the rest position via a handwheel.

This makes changing the machining planes quick and easy.

The main aggregates of our machines are arranged in a maintenance-friendly way. All important

units are located for direct access at the rear. In addition, you benefit from automatic central lubrication for all axes and the vertical milling head.

With the performance and accessibility of our machines, they surprise with a compact footprint. This means that our FPS 425M-NC and FPS 630M-NC Dualmasters also suit workshops with little installation space.

FPS 300 M | FPS 500 M | FPS 500 M hydro

FPS 500M-digital | FPS 630M-digital

FPS 420 M-NC | FPS 620 M-NC